( THAILAND )

More information click: Specifying GRC, GRC Standards and testing, NEG ARG FIBRE, Discussion Paper

BASICALLY IT'S CONCRETE.

REINFORCED WITH GLASSFIBRE INSTEAD OF STEEL.

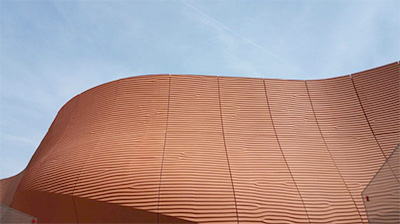

GRC WITH INTEGRAL COLOUR AND TEXTURE.

IT'S BEEN IN USE FOR ABOUT 45 YEARS.

IT IS IMPORTANT TO UNDERSTAND THAT GRC REQUIRES SPECIAL MATERIALS, SPECIAL EQUIPMENT, TRAINED OPERATIVES AND RIGOROUS Q.A.

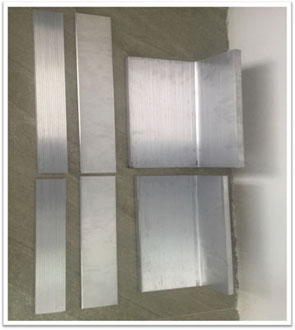

Example of Sprayed Grade 18(p) GRC manufactured to comply with relevant international specificationsand standards.

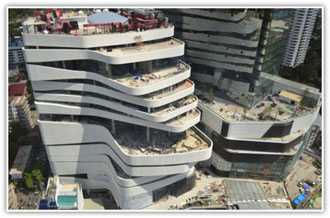

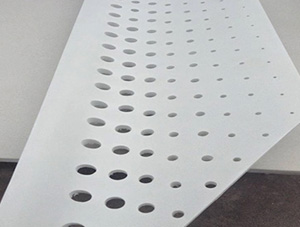

GRC: the material can be used in a multitude of different designs and bespoke applications

Using 3D software, CNC lathes are used to manufacture moulds.

Zero damage, robust mould, dimension control, CNC profile.

This ensures a controlled and uniformed colour during the complete manufacturing process.

Durable and strong Easily removed